LINDAPTER®, ASSEMBLY SOLUTIONS FOR A WIDE RANGE OF INDUSTRIES.

The Lindapter story began in 1934, when engineer Henry Lindsay invented a completely new concept in structural steel connection using the Lindsay Bolt Adapter: this solution enabled rapid assembly of steel beams, without wasting time drilling or welding. To create the now famous brand, Henry combined the name Lindsay with the English word "adapter".

Today, Lindapter remains true to its origins, continuing to invent and manufacture quality products that save companies time and money.

Unique in their kind, Lindapter assembly systems can be installed with standard hand tools, speeding up construction, reducing labor costs, and allowing adjustments to be made on site, without damaging metal sections.

THE WORLD OF LINDAPTER®

Since 1934, Lindapter has been constantly developing its product range, offering products for almost every metal joining application. In addition to its flagship products, the Hollo-Bolt and structural clamps, Lindapter has specialized in other product groups detailed below.

Hollo-Bolt®

A family of expansion bolts for rapid assembly of pre-drilled hollow sections that are only accessible from one side.

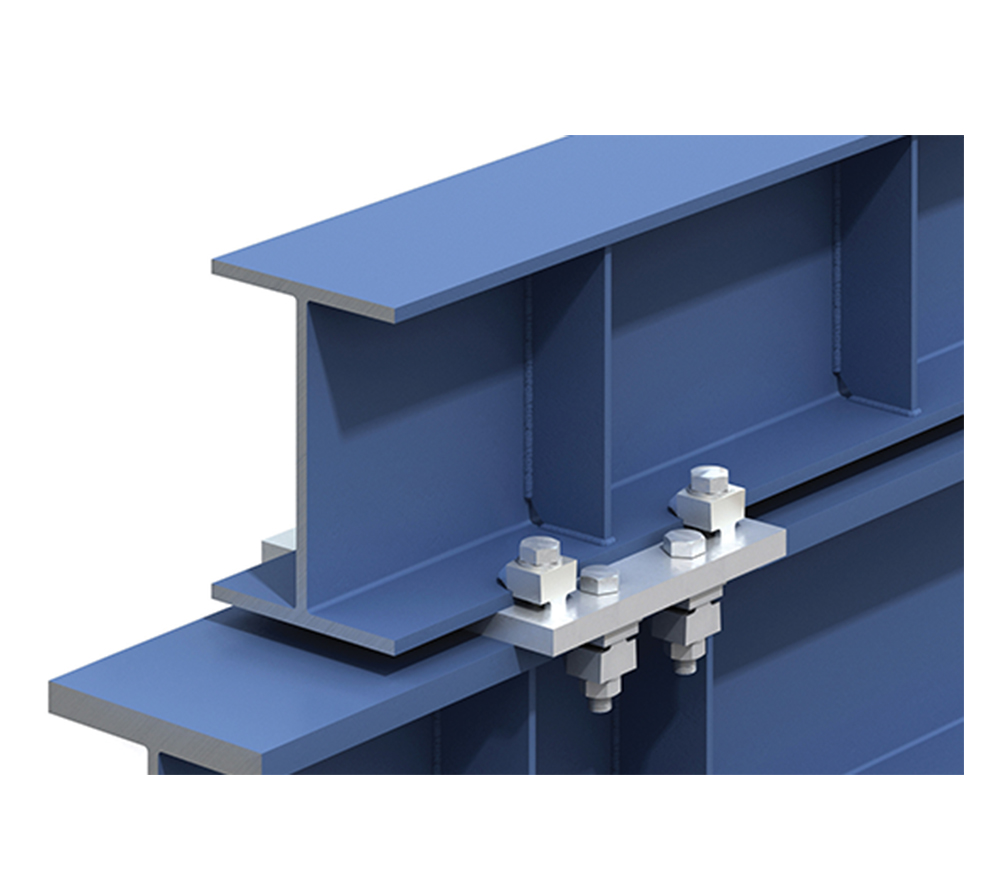

Beam assembly clamps

Sections are clamped together using high-strength connection systems configured to specific requirements, without damaging the structure, to withstand, for example, tensile/slip forces of 250 kN / 70 kN.

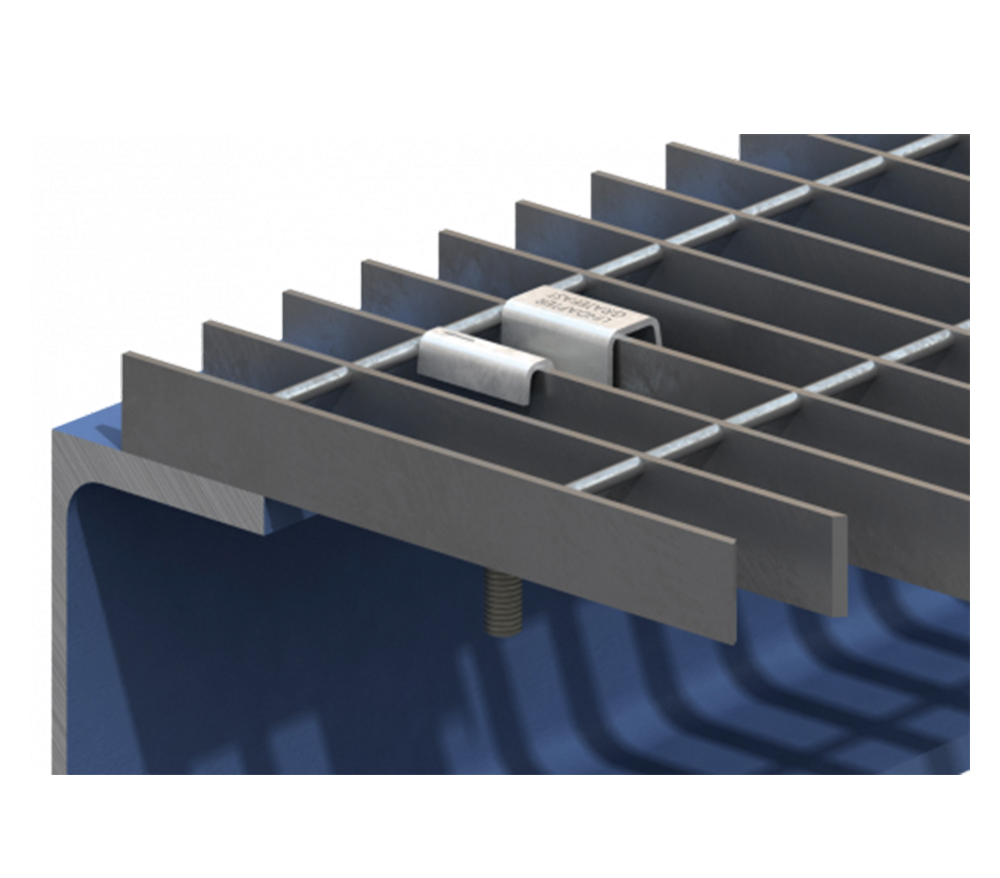

Floor fasteners

A range of innovative fasteners for joining metal floors to supporting structures without the need for drilling or welding on site. Installation can be carried out quickly and safely from above.

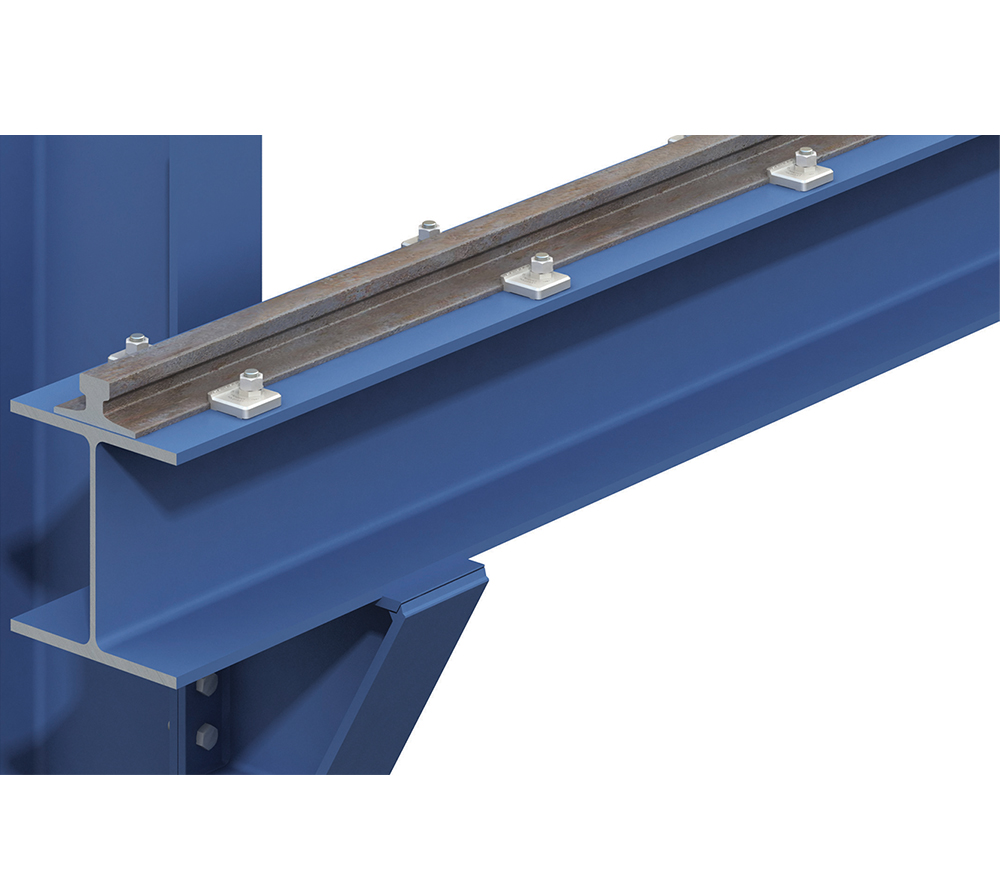

Rail fasteners

Low-speed track rails are secured with practical, easy-to-install products such as the Type HD clamp, allowing lateral adjustment at the time of installation.

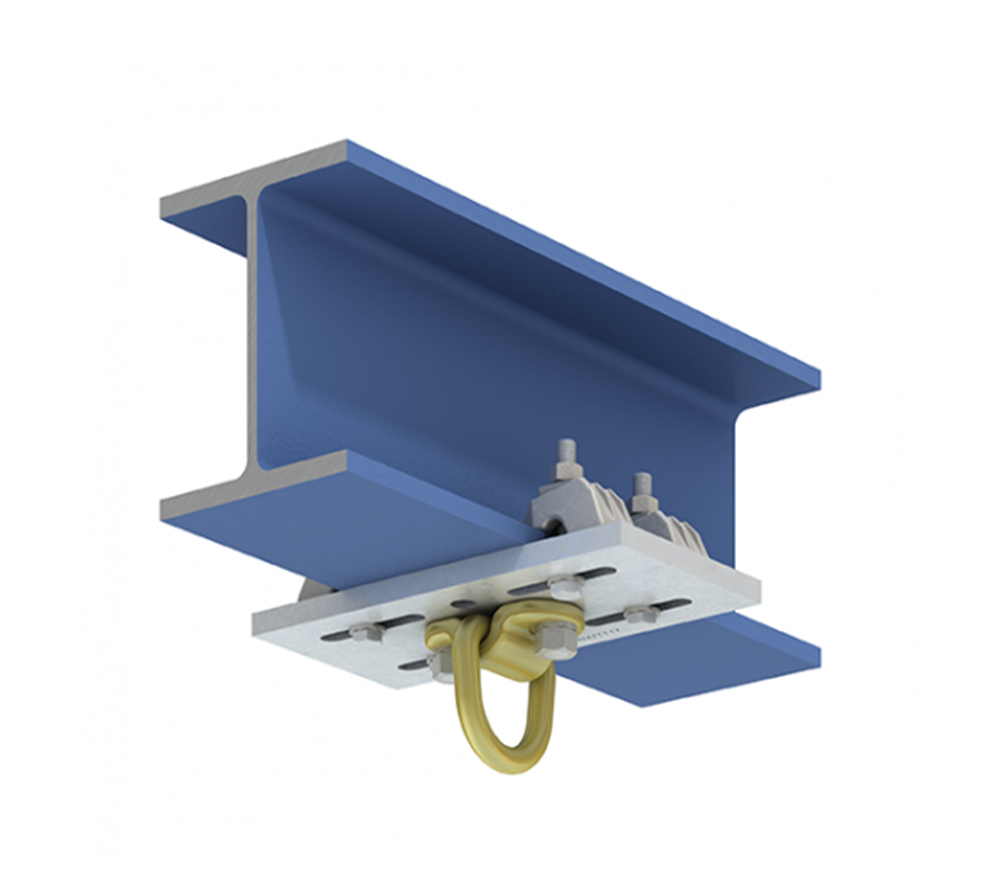

Lifting points

These assemblies support the hooking or lifting of equipment in general. They can be used for lifting alone or for permanent applications, such as lighting booms and hanging systems in theaters.

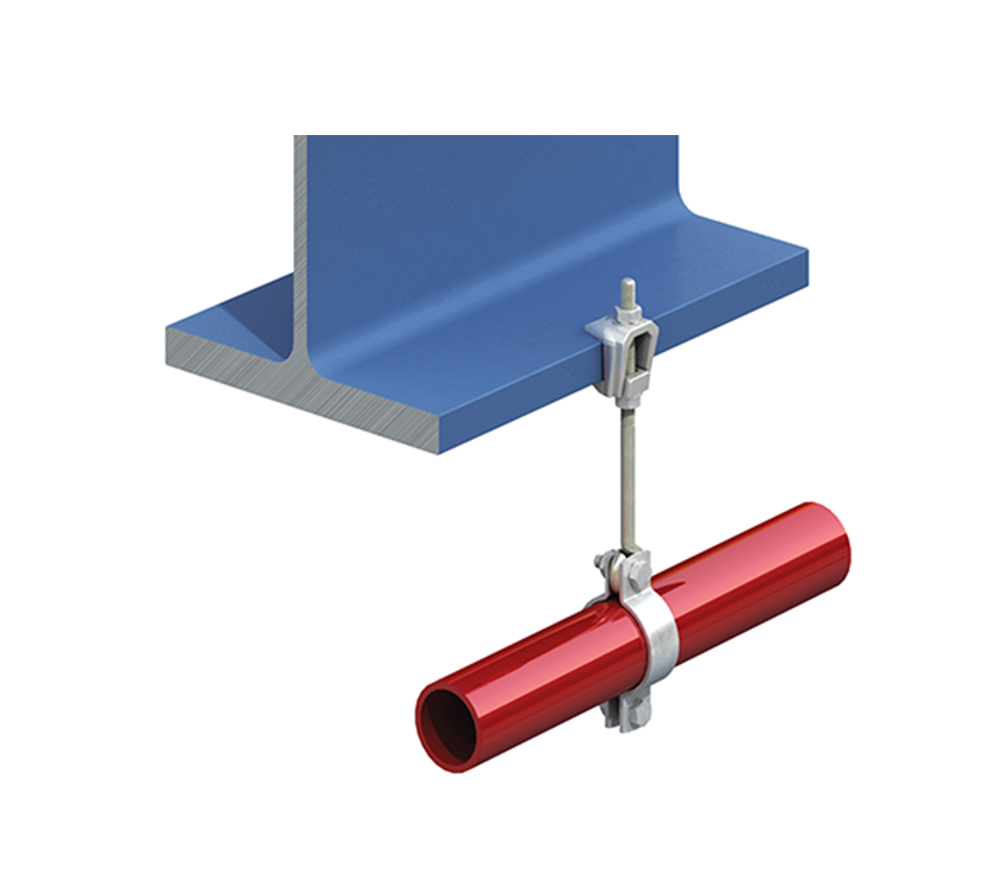

Hanger brackets

Easy-to-install solutions for suspending networks in buildings from structural or secondary beams. These products' adjustability makes it easy to position pipes and other equipment.

KEY BENEFITS OF LINDAPTER® PRODUCTS

SAVE TIME AND MONEY

Lindapter clamps enable faster assembly than welding, or drilling and bolting.

HIGH STRENGTH

High-strength materials for heavy-duty applications and aggressive environments.

FIELD-ADJUSTABLE

Quickly aligned by adjusting to the desired position, before tightening with hand tools.

SAFER ASSEMBLY

No on-site drilling or welding, resulting in safer on-site working conditions and eliminating the need for fire permits.

TECHNICAL INNOVATION IN METAL CONSTRUCTION ASSEMBLY.

For over 85 years, Lindapter has earned a reputation and respect as a pioneer of fastening systems in steel construction, growing from a modest family business to a world-renowned brand by inventing a faster solution than welding or drilling and bolting.

Typical applications include connections for:

- Beams

- Hollow sections

- Pipe supports

- Lifting points

- Facades and cladding

- Floors

LINDAPTER® LIBRARY:

Discover our Lindapter® media library: product catalog, presentation brochure and company information. One-click access to essential resources for learning more about this brand.

Benefit from comprehensive, up-to-date documentation to meet your professional needs.