SUPERBOLT® MECHANICAL TENSIONERS

FOR EASIER BOLT TIGHTENING

NORD-LOCK GROUP, A HOTBED OF INNOVATION AND ENGINEERING

Nord-Lock Group offers the technologies you need to meet your bolting challenges. In 1982, the original Nord-Lock® cam-locking technology that truly secures bolted assemblies was developed.

Since then, our range of technologies and assembly expertise has become the most comprehensive on the market, incorporating Superbolt® mechanical tensioners , Boltight® hydraulic tensioners and Expander® pins.

All solutions are developed and manufactured in-house, ensuring that they meet the highest industry standards.

Our dedicated team of experts works closely with customers all over the world.

How does it work?

DESIGNED FOR YOUR BOLTED JOINT CHALLENGES

Examples of solutions for all applications and sectors:

Superbolt was the first in the world to revolutionize nuts and bolts with the MJT multi-screw tensioner. Our technology was invented in Pittsburgh, Pennsylvania, USA, in 1984, and has since proven itself in thousands of successful installations worldwide. As a testament to its commitment to quality, Superbolt is ISO 9001: 2015 certified. Most recently, the Superbolt Tool received the prestigious Red Dot Award for "Best Product Design 2020" in the Innovation category.

We understand that every industry has its own challenges. In our wide range of products, you can find solutions for your specific needs, and we continue to develop a multitude of solutions to solve the assembly challenges of future generations. Whether you need to replace existing bolts to achieve a precise preload safely, want to increase the fatigue strength of the bolt or stud, have rotating couplings or a restricted-access application, there's a solution in our product range. We also offer tensioners with integrated smart technology that allows you to monitor preload remotely.

Need a customized solution for a specific need?

When off-the-shelf parts simply won't do the job, you can rely on our dedicated team of engineers to share their experience, knowledge and creativity to design a solution that meets the specific requirements of your application. We have manufactured special products up to 1500 mm diameter and products for operating temperatures of 700°C (1292°F).

Our customized solutions can also be developed from pre-designed solutions, combine several technologies or be integrated into the design of other parts.

THE CHALLENGE

CREATING ENOUGH LOAD ON LARGE BOLTED ASSEMBLIES

For large bolts, it is becoming increasingly difficult to create sufficient load using torque tightening methods. Many traditional methods can lead to serious problems, including injury, inaccurate preload, thread damage, difficult disassembly, equipment cost and excessive downtime.

THE SOLUTION

DIVIDE TORQUE INTO MULTIPLE MANAGEABLE FORCES

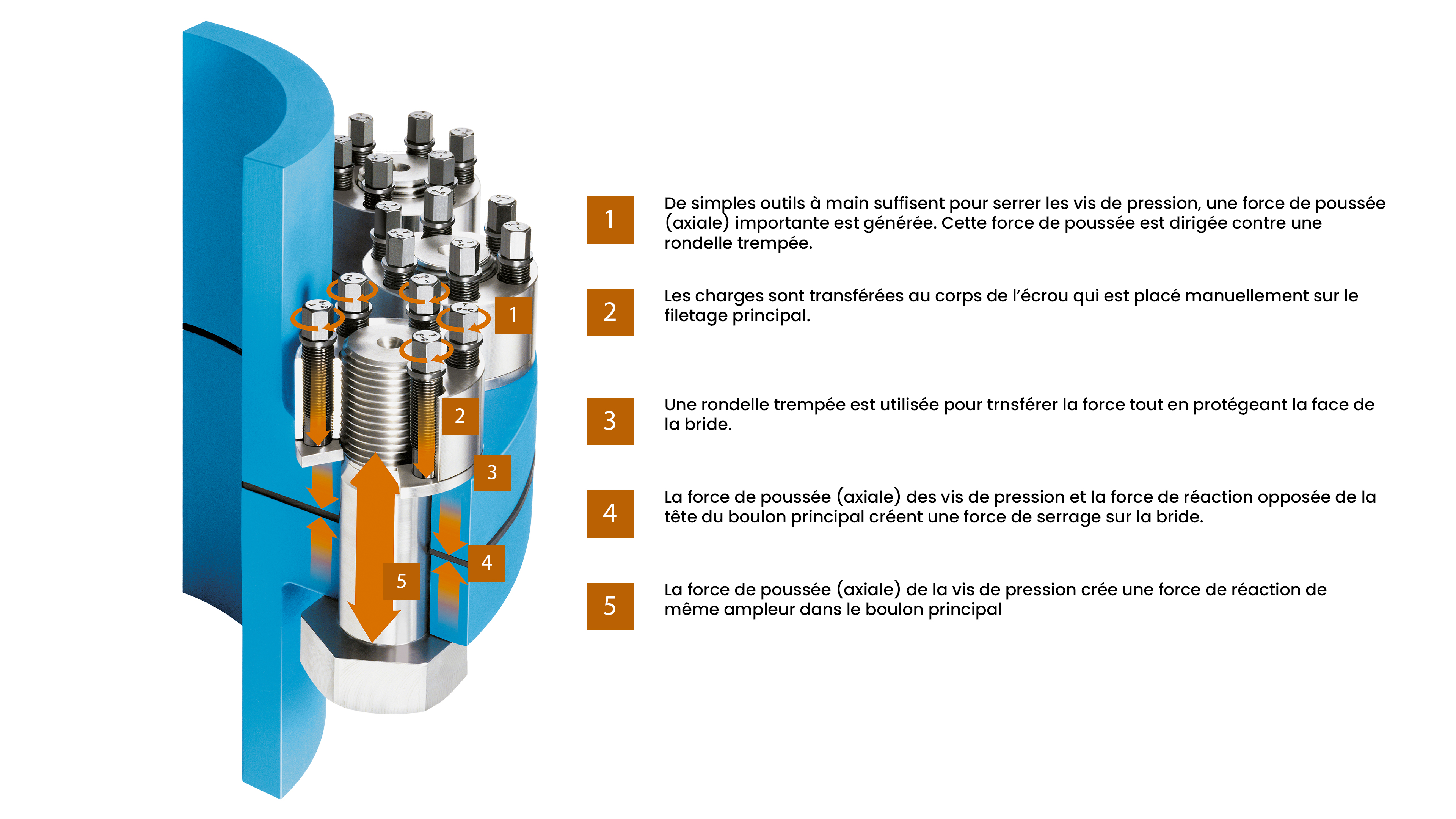

Superbolt Multiple Screw Tensioners (MJT) achieve incredibly high preloads and precision by dividing torque into multiple manageable forces using the set screws and nut body. Your assemblies can be tightened without the need for specialized skills or heavy tools. Only simple hand tools are required for installation. It's a fast, safe and efficient operation.

SIMPLIFIED BOLTING

Superbolt tensioners offer simple, economical tightening of large bolts. They are designed to replace hexagonal or other nuts and bolts directly.

Benefits :

- Quick and easy installation and removal

- Only hand tools required

- Safe method of installation

- Cost-effective life cycle

- Reliable operation