This piece is packaged in boxes of

10 units.

We apply a surcharge for deconditioning according to the following rules

| Quantity | Price |

|---|---|

| 10 piece(s) | 27.14126 € |

| 1 unit | 36.41453 € |

M24 Type A Lindapter Medium Zinc plated white - LINDAPTER®

![]() Express delivery 24–48 hours in mainland France

Express delivery 24–48 hours in mainland France

![]() Verified stock in real time

Verified stock in real time

![]() Degressive pricing and larger quantities available on request

Degressive pricing and larger quantities available on request

Specifications

Description :

Introduction :

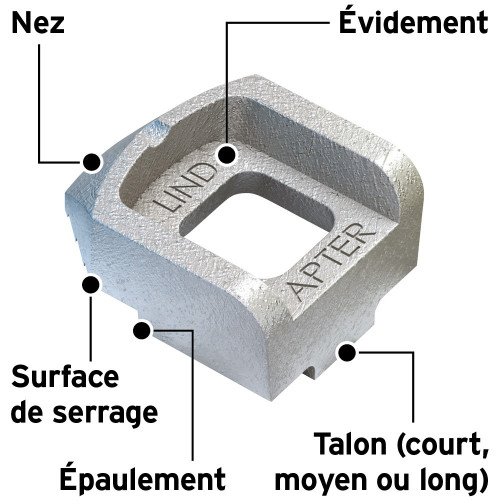

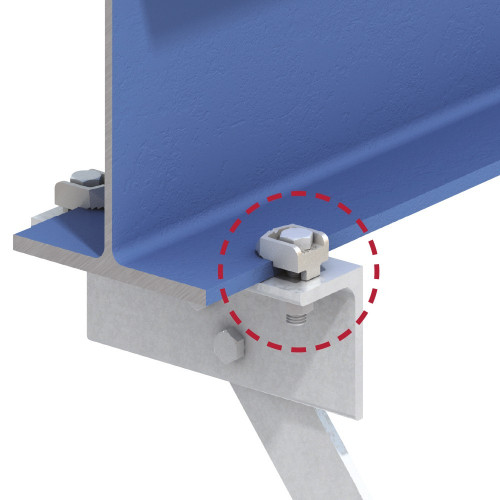

The Type A fastening clamp provides a quick connection system between two steel beams. It is often used in conjunction with the Type B clamp. The recessed upper part holds the bolt head captive while the nut and washer are tightened, using a single tool. The shoulder on the reverse side wedges itself to the edge of the beam flange, preventing the clamp from turning during installation. Type A clamps can also be used on their own, if one of the two metal profiles has been pre-drilled.

Options and benefits :

- Recessed top holds bolt captive while nut is tightened.

- Ideal for parallel wings.

- Supports up to 78.8 kN in tension in a four-bolt configuration.

Heel lengths and shims:

Available in three heel lengths - Short, Medium and Long - the clamp can be combined with Lindapter shims to increase the clamping range. Choose the combination of heel length and number of wedges to suit your wing thickness. For the selection table, download the data sheet below.

Positioning and end plates :

These plates ensure correct positioning of the clamps and bolts in relation to the support structure. Positioning plates are simple fabricated parts designed to be inserted between the two profiles to be joined, to ensure that the bolts are correctly centered during installation. End plates are simple fabricated parts that are pre-welded to support structures, brackets or profiles, to enable assembly to the support structure using standard Lindapter clamps. For further information, download the data sheet below.

Properties :

- Made of malleable cast iron to EN 1562 standard.

- Available in galvanized or hot-dip galvanized finish.

- Reaction to fire: A1 (Steel).

Technical Specification :

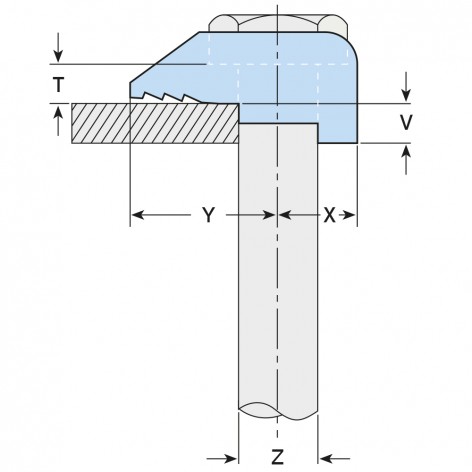

| Working loads (Safety factor 5:1) | Dimensions | ||||||||||

| Product code | Bolt 8.8 Z | Tension / 1 bolt | Sliding / 2 bolts | Tightening torque | Y | X | Heel length V | T | Width | ||

| kN | short | medium | long | ||||||||

| kN | Nm | mm | mm | mm | mm | mm | mm | mm | |||

| A08 | M8 | 1 | - | 6 | 16 | 8 | - | 4 | - | 4 | 20 |

| A10 | M10 | 1.5 | - | 20 | 20 | 11 | 4 | 5 | 7 | 5 | 26 |

| A12 | M12 | 5.8 | 0.9 | 69 | 26 | 13 | 4.5 | 6 | 9.5 | 6 | 29 |

| A16 | M16 | 8.5 | 1.7 | 147 | 30 | 16 | 5.5 | 8 | 11 | 8 | 36 |

| A20 | M20 | 14.7 | 3 | 285 | 36 | 19 | 7 | 10 | 12.5 | 10 | 46 |

| A24 | M24 | 19.7 | 4.5 | 491 | 48 | 25 | 9 | 12 | 16 | 13 | 55 |

* Torque values are based on unlubricated, uncoated bolts.

Suitable for UPN / IPN inclined flanges. For further information, please contact Lindapter Technical Support.